CLP pick & place casepacker

The CLP case packer is a Pick & Place unit for packing f.e. MAP trays, flowpacked products, skinpacks and many others horizontally into cases, cardboard trays and crates.

Request for quoteFunctional description

The products may be rigid, semi-rigid or flexible.

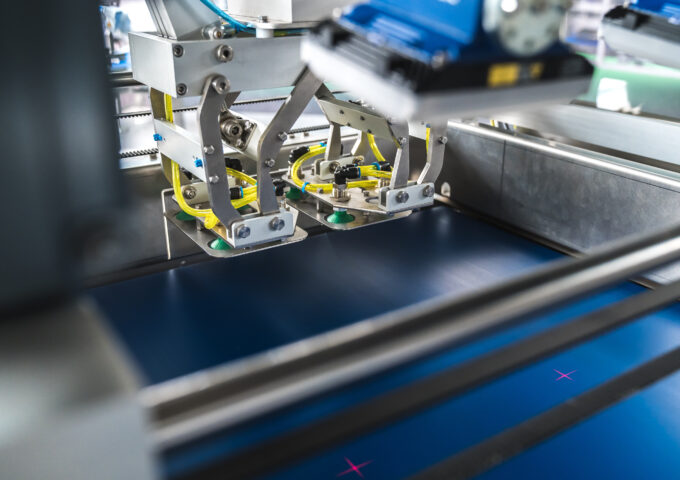

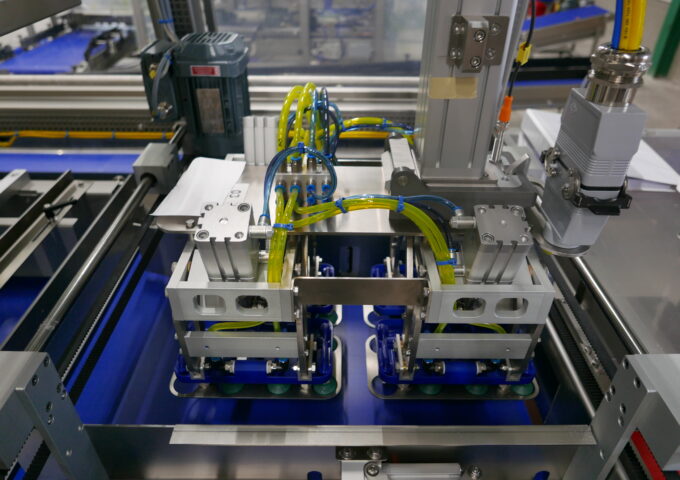

This system loads products into crates, cases or trays fully automatically, products are packed on the fly without buffering. The products may be rigid, semi-rigid or flexible. They can be turned or left in original orientation, what creates a huge variety of packing patterns as a result. The pick-up head picks up the products as the retracting conveyor under the products opens and the head (only vertical movement) places a complete layer of products into the case, crate or tray.

Looking for flexibility?

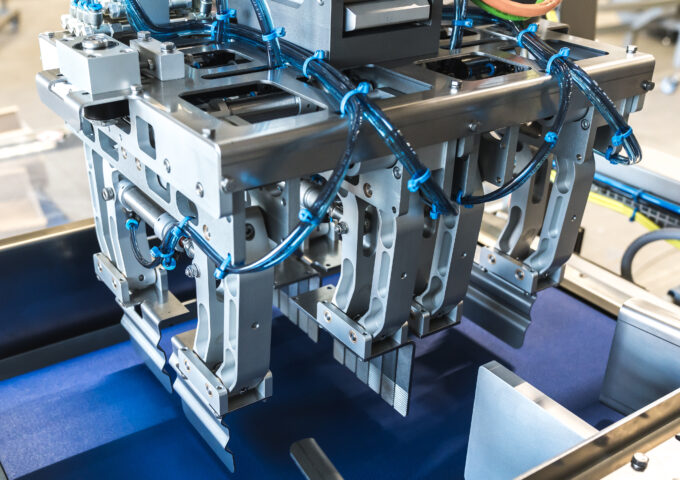

There are several different pick and place heads developped for the CLP, flat or hinged vacuum or clamp supported all depending on the type of carrier used and product to be packed. This flexibility enables us to pack various kinds of products at high speed in various types of carriers like cases, crates and or trays even with stagging shoulders. Multiple layers are possible.

Extremely reliable

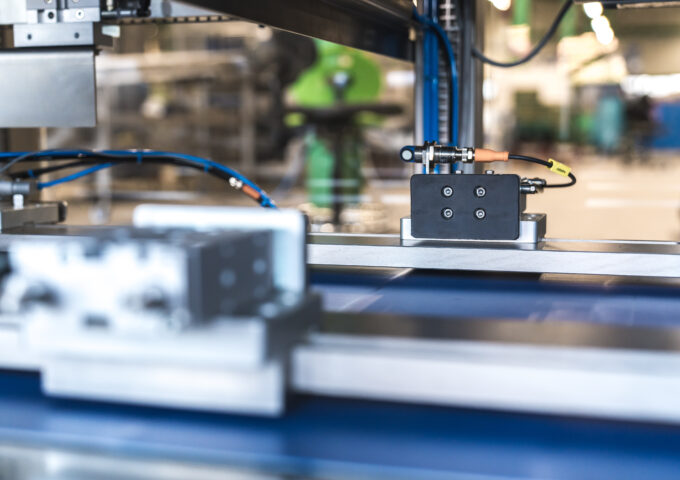

Because the products are only placed vertically downwards in the product carrier, the system is extremely reliable at high capacity. Because an entire layer is placed in one go, the speed of the P&P head is controlled smoothly, so that sensitive products can also be packed. The CLP is menu controlled, what makes it possible to switch quickly from one to another product and/or product carrier without using any tools.

Crates, cases and carton trays

The CLP can handle crates, American syle cases and cardboard trays, which means that the CLP can be used in a flexible way. Resulting a short payback time.

Features

Why our CLP can be an added value to your production!

- Proven technology.

- Gentle product handling, even for the highest sensitive products (f.e. straw- and blueberries)

- Only vertical movement, (no issues with weights)

- Flexible in packing patterns, high speeds and no buffering.

- Wide range of carriers can be used, with and without stagging shoulders!

- User friendly. New programs made over our wizard.

- Maintenance friendly. Open and robuust construction, easy accessibility.

- Standard remote access.

- Reduction of downtime. Menu controlled where possible!

- Easy integration / combination of third party equipment.

Technical properties

Product data CLP pick & place casepacker

| General dimensions | Length: 3150 - 2300 mm / 124” - 90.5” Width: 1470mm / 57.7” Height: 2000mm / 78.7” |

| Product infeed height | 900 - 1200mm / 35.4 - 47.2” |

| Case infeed height | 450mm / 17.7” |

| Electrical supply | 3fase 400V + N + PE 50Hz 3,1kW 16A |

| Compressed air supply | 350 Nl/min, 6bar |

| Weight | 1200kg, (3200lbs) |

| Case / crate dimensions | Length: 300 - 600mm / 11,8" - 23.6” Width: 200 - 400mm / 7.8" - 15.8” Height: 100 - 300mm / 3,9" - 11.8” |

| Capacity | Up to 160 Products/min; Up to 20 cases - crates/min |